Want to maintain inspection quality but

Lack of skilled personnel

In work site safety management

I want to lower my labor costs.

To increase competitiveness

To improve operational efficiency

Inspections to ensure that piping is free of rust are currently performed prior to delivery of goods to customers. However, human inspection is time-consuming and labor intensive. There is also the problem that clear standards and rules regarding the degree to which rust is acceptable are not shared with customers.

To solve these problems, Arayaacquires inspection images of each facility, inspects the structure, and extracts specific images from the 360-degree camera images to streamline the inspection process and save manpower.

Rust/corrosion on various structures such as bridges and steel towers can be detected from the captured images.

Detection results can also be classified into various ranks according to inspection requirements.

Cracks in an image are estimated using a domain segmentation model of the image as input values. Cracks that occur in various structures, such as buildings, can be detected from the captured images.

THE AI IDENTIFIES PRIORITY INSPECTION POINTS TO SHORTEN INSPECTION TIME AND REDUCE THE VARIATION IN INSPECTION QUALITY AMONG INSPECTORS.

At some sites, such as forklift sites, workers may not comply with safety measures. In addition, safety management is conducted at construction sites by capturing video with a digital camera, but visual checks are labor- and time-intensive, inefficient, and impose a heavy workload on workers.

ARAYAUSES AI IMAGE ANALYSIS TO IDENTIFY THE POSITIONAL RELATIONSHIP AND PROXIMITY DISTANCE BETWEEN THE WORK VEHICLE AND WORKER, AND NOTIFIES THE USER OF ALERTS. EVEN IN CHALLENGING SITUATIONS, SUCH AS BLOCKED OR UNSEEN, OUR UNIQUE ALGORITHMS CAN HANDLE THE SITUATION.

Identifies vehicles, pedestrians, motorcycles, and bicycles. Identifies non-vehicular objects and vehicles entering the intersection area, vehicles entering an intersection area, and objects other than vehicles and objects other than vehicles that enter the intersection area and are in close proximity to vehicles are identified and displayed.

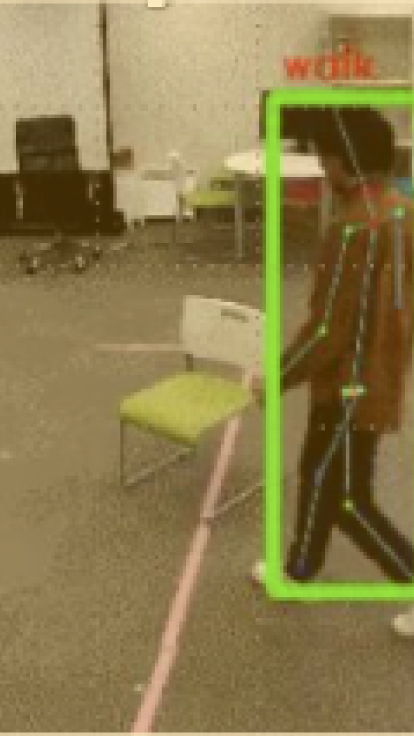

Visualize and analyze workers' hazardous behavior and take measures to improve safety.

and take measures to improve safety.

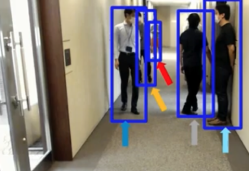

ARAYAS HUMAN FLOW BEHAVIOR ANALYSIS SOLUTION USES IMAGE RECOGNITION AI TO DETECT MOVING PEOPLE AND ACQUIRE AND VISUALIZE LOCATION INFORMATION. THIS CONTRIBUTES TO STORE OPERATIONS AND MARKETING, AS WELL AS FACTORY AND WAREHOUSE WORK EFFICIENCY.

THE SOLUTION CAN COMBINE AND ANALYZE A PERSON'S PATH OF TRAVEL WITH ATTRIBUTES SUCH AS AGE AND GENDER, PROVIDE CUSTOMIZABLE APPLICATIONS AND SERVICES, AND CAN BE AN ADD-ON TO EXISTING CAMERA SYSTEMS THROUGH THE USE OF EDGE AI TECHNOLOGY.

IT IS A USEFUL TOOL FOR UNDERSTANDING CUSTOMER PURCHASING PATTERNS AND OPTIMIZING STORE LAYOUT AND MARKETING STRATEGIES. USING AI TO ANALYZE HUMAN BEHAVIOR IS A GREAT WAY TO HELP ANALYZE AND UNDERSTAND CUSTOMER BEHAVIOR.

The flow and location of people and their numbers can be quickly and accurately identified and analyzed. This allows for immediate understanding of congestion at specific times and locations.

VISUALIZATION OF HUMAN FLOW AND HEADCOUNT COUNT BY IMAGE RECOGNITION AI ENABLES UNDERSTANDING OF CONGESTION, EFFICIENCY, SAFETY MEASURES, AND OPTIMIZATION IN STORES, EVENTS, TRAFFIC, OFFICE MANAGEMENT, ETC. REAL-TIME, HIGHLY ACCURATE ANALYSIS IS POSSIBLE, SUPPORTING RAPID DECISION-MAKING.

Listed in Japanese alphabetical order

ArayaFor more information about the image recognition AI solutions offered by the company and its website, please visit the website.

is a wealth of case studies that are not listed.

ARAYAIMAGE RECOGNITION AI SOLUTION PROVIDED BY

The details of the project and the website are posted on the website.

Here are a wealth of examples that are not.